[Answered & Explained] Does Size Matter in Capacitor?

Capacitors are crucial passive components in the electronics industry, used for coupling, decoupling, power supply filtering, signal filtering, impedance matching, energy storage, and snubber action.

Their size varies based on application, with factors like voltage, current ripple, temperature, and leakage current influencing the selection. Capacitor size selection is crucial for circuit assembly and performance variation. Let’s discuss capacitor size and the parameters that influence it in this article.

What Size Capacitor Should You Use?

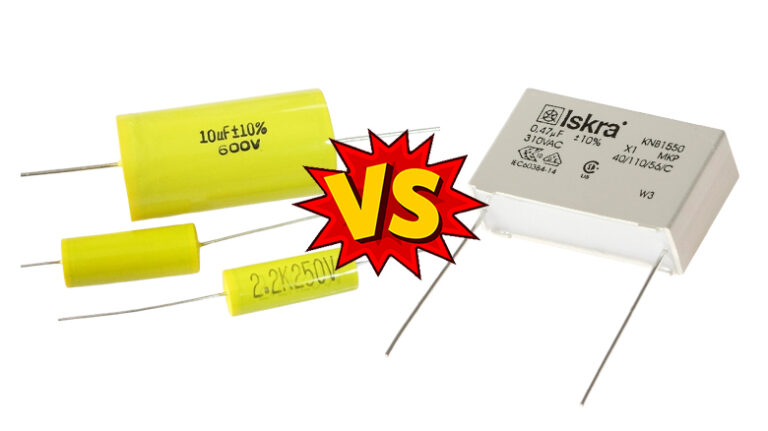

It might be difficult to choose a capacitor that is the right size. Capacitance, voltage, ripple current, and temperature should all be considered while choosing a capacitor. The fluctuation in each of these factors affects the physical size of the capacitance, and the size variation differs for each type of capacitor, including paper capacitors, mica capacitors, ceramic capacitors, and electrolytic capacitors.

The major parameters guiding capacitor size selection are:

1. Nominal Capacitance

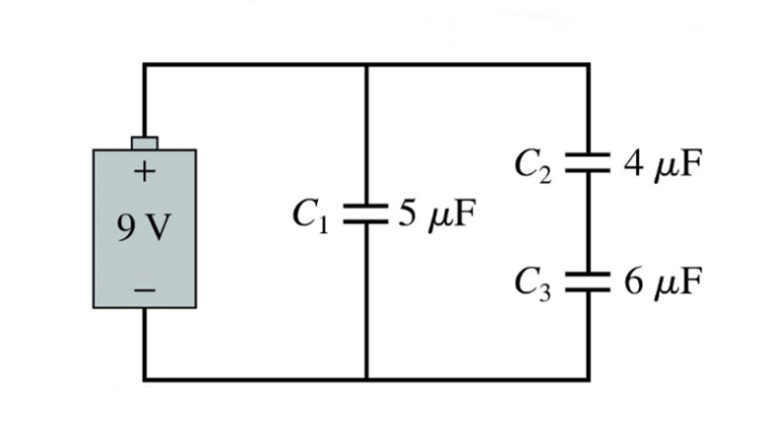

The nominal capacitance value needs to be the main factor in choosing a capacitor. The application must be understood to calculate the capacitance value. In an integrated circuit application, the capacitance is either calculated by the designer or suggested in the IC datasheet. The capacitor type is chosen by the needs of the circuit and the anticipated characteristics of the capacitor.

Some common capacitor types include:

- Pico-farad range ceramic capacitors

- Nano-farad multilayer ceramic capacitors (MLCC)

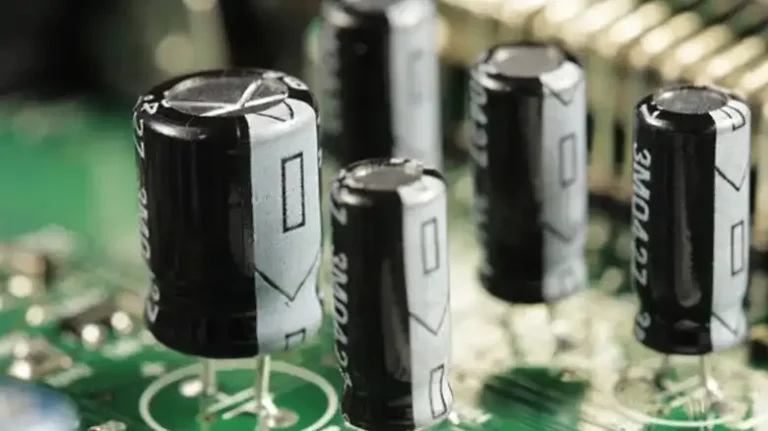

- Micro-farad aluminum electrolytic capacitors

- High-temperature range mica capacitors

2. Tolerance

It is important to take into account the capacitor’s tolerance since it provides details on the real variation in capacitance permitted. For precise applications, a lower-tolerance capacitor should be chosen since a higher-tolerance capacitor is not appropriate.

There are capacitors available with the same capacitance but varying amounts of tolerance. The capacitance value determines the physical size of the capacitor; as the capacitance rises, the size expands.

3. Working Voltage and Ripple Current

The voltage rating is the maximum continuous DC or AC voltage a capacitor can withstand without failing, and exceeding it can damage it. Capacitors are derated by selecting one that is two to three times greater than the expected operating voltage. This increases the footprint requirements and physical size of the capacitor.

In practical applications, ripple current or leakage current flows through the dielectric, and the ripple current rating must be considered. Film capacitors are recommended for electrolytic capacitors with less ripple current rating and high ripple content withstanding capabilities.

4. Operating Temperature and the Temperature Coefficient

The operating temperature is a crucial environmental factor in capacitor selection. Datasheets provide temperature ratings, and selecting a higher rating than the actual application temperature is appropriate. However, it’s crucial to provide a temperature margin to accommodate thermal rise due to internal heating, as insufficient margin can cause capacitor explosion.

5. Capacitor Variation

When working with temperature-sensitive circuits or applications, consider capacitor fluctuation vs. temperature. Temperature affects capacitance changes, so choose the capacitor with the least temperature coefficient for wide temperature control. Ensure adequate board room for high and broad temperature applications.

Applications of Different Capacitor Sizes

Based on the particular needs of an electrical circuit, the size of a capacitor is selected. The following uses and associated capacitor sizes are typical:

- Smaller Capacitors: For high-frequency filtering, bypassing, and coupling applications, smaller capacitors are frequently utilized. They are frequently found on integrated circuits (ICs) and in RF (radio frequency) circuits and are useful in smoothing out voltage fluctuations in electronic circuits.

- Medium-Sized Capacitors: Capacitance and physical size are balanced in medium-sized capacitors. They are utilized in a variety of applications, such as timing circuits, decoupling, and power supply filtering.

- Larger Capacitors: Larger capacitors are utilized for energy storage and voltage control and usually have greater capacitance values. For instance, electrolytic capacitors are frequently used in power supply circuits to maintain voltage levels.

Frequently Asked Questions and Answers (FAQs)

Q1. Is it better to use a bigger or smaller capacitor?

Ans: Larger capacitors are frequently used for lower frequencies whereas smaller capacitors are used for higher frequencies. The tendency is not general, especially for DC bias, thus it is also crucial to verify datasheets.

Q2. Can I use a 7.5 capacitor in place of a 5?

Ans: Yes, you can swap out a 5 for a 7.5 capacitor. However, in the majority of situations, it depends on the application and other capacitor characteristics, such as voltage. In a capacitive circuit, when capacitance rises, capacitive reactance XC falls, increasing circuit current, and vice versa.

Q3. Is it okay to use a higher UF capacitor?

Ans: It varies per circuit; it’s not always the case. There will be greater inrush current and perhaps more damage if it is in a power filter. It will have an impact on frequency response if it is in the analog signal path.

To Conclude

Capacitors, used in electronics, have varying sizes and performances in various applications. Their capacitance, influenced by size, is crucial for engineers to construct circuits. Understanding this connection is essential for good electrical circuit design, as size matters for optimal performance.