Can I Replace Electrolytic Capacitor With Polymer? Easy Explanation

As long as the maximum rated voltage is not exceeded, polymer capacitors can typically be utilized as straight replacements for electrolytic capacitors. Also, capacitance value, ESR, polarity, form factor, etc should be considered.

Although certain solid polymer capacitors are created with maximum working voltages of up to 100 volts DC, the maximum rated voltage of solid polymer capacitors is often up to 35 volts, which is lower than the maximum voltage of conventional electrolytic capacitors.

Is It Safe to Use Polymer Capacitors in Place of Electrolytic Capacitors?

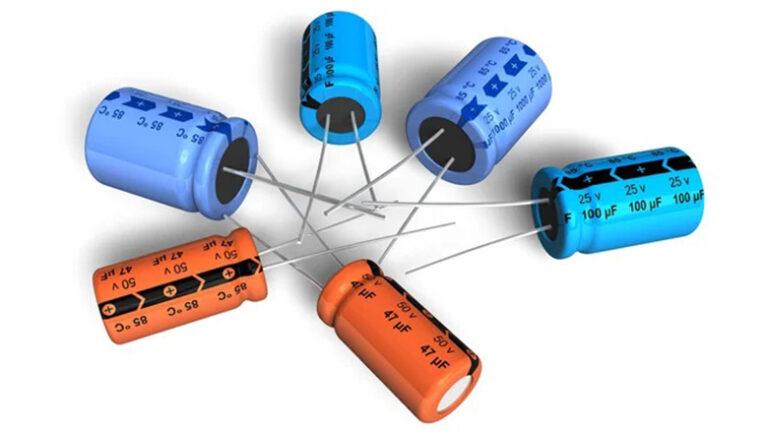

In many instances, a polymer capacitor—also referred to as a solid electrolyte capacitor or conductive polymer capacitor—can be used to replace an electrolytic capacitor. Due to its benefits over conventional electrolytic capacitors, polymer capacitors have grown in popularity in recent years.

Conductive polymers are used as the electrolyte in polymer capacitors, which are capacitors. They use solid polymer electrolytes instead of liquid or gel electrolytes in typical electrolytic capacitors. Drying of the electrolyte can be fully avoided by utilizing solid electrolytes. Here are a few considerations for safely Use Polymer Capacitors.

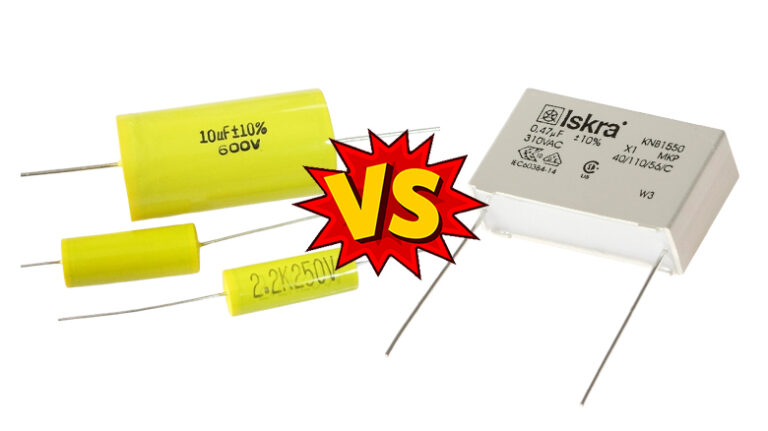

Fig. 1: Comparison of polymer (solid) capacitor and electrolytic capacitor in terms of frequency vs impedance

1. Voltage Rating

Compared to polymer capacitors, electrolytic capacitors are frequently offered with higher voltage ratings. The advantages come at a higher price than wet electrolyte capacitors, along with a shorter capacitance range and lower maximum voltage rating.

For instance, a polymer capacitor might have a lower voltage rating, like 16V or 25V, compared to an electrolytic capacitor, which might have a voltage rating of 50V or 100V. Make that the voltage rating of the polymer capacitor is equal to or higher than the voltage in the circuit where it will be utilized when replacing an electrolytic capacitor.

2. High Capacitance Specifications

Electrolytic capacitors might be better if your circuit demands a high capacitance value. Particularly in the high capacitance range, polymer capacitors often have lower capacitance values than electrolytic capacitors.

For instance, a polymer capacitor may have a smaller capacitance value, such as tens or hundreds of microfarads, compared to an electrolytic capacitor, which may have a capacitance value of several hundred or thousands of microfarads (F).

When substituting, make sure the capacitance value of the polymer capacitor meets or surpasses the value needed in the circuit. Using several polymer capacitors in parallel in such circumstances might be a remedy, although it might not always be feasible.

3. Equivalent Series Resistance (ESR)

ESR is the term for a capacitor’s internal resistance, which can have an impact on how well and efficiently it works. ESR values for polymer capacitors are often lower than those for electrolytic capacitors. Better high-frequency performance and increased circuit stability are made possible by lower ESR.

For instance, a polymer capacitor may have an ESR value in the milliohm range, whereas an electrolytic capacitor may have an ESR value of several ohms. Make sure the chosen polymer capacitor has a low enough ESR for the proper functioning of the circuit depending on the electrolytic capacitor’s unique ESR properties.

4. Polarity

While most polymer capacitors are non-polarized, electrolytic capacitors are polarized, having both a positive and a negative terminal. Polymer capacitors are often non-polarized, allowing them to be wired in any direction.

But it’s essential to follow the circuit’s polarity specifications. When using a non-polarized polymer capacitor, check the polarity indications on the original electrolytic capacitor and make sure the connection is proper.

5. Current Applications Surge

High surge current handling capacity is a well-known characteristic of electrolytic capacitors. The replacement is not advised if your circuit experiences frequent or sizable surge currents.

- Electrolytic Capacitor

An electrolytic capacitor’s surge current rating is influenced by things like its size, structure, and intended use. Electrolytic capacitors can often withstand surge currents of tens to hundreds of amps.

It’s crucial to remember that the capacity to handle surge current can degrade with more frequent use. greater voltage-rated capacitors frequently also have greater ratings for surge current.

- Polymer Capacitor

Surge current ratings for polymer capacitors are often lower than those for electrolytic capacitors. Depending on the particular model and manufacturer, polymer capacitors’ capacity to handle surge currents can change.

Surge current ratings for polymer capacitors typically range from a few amperes to tens of amperes. To ascertain the surge current rating of a given polymer capacitor, it is crucial to consult the datasheets or manufacturer’s specifications.

6. Cost

Particularly in higher capacitance and voltage ranges, polymer capacitors are typically more expensive than electrolytic capacitors. It might not be economically feasible to go from electrolytic to polymer capacitors if cost is a major concern for your project.

7. Measurements and Form Factor

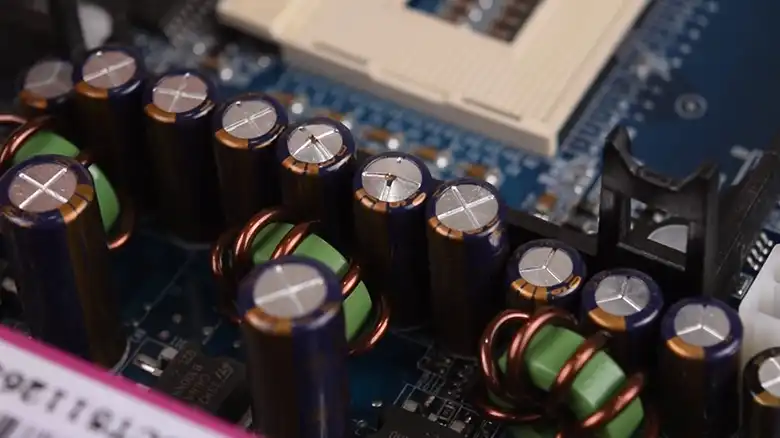

Capacitors exist in a variety of shapes and sizes, which may affect how physically compatible they are with a circuit or other device. Compared to polymer capacitors, electrolytic capacitors typically have larger physical dimensions.

Make sure to take the size and form factor into account when changing an electrolytic capacitor with a polymer capacitor to make sure the replacement will fit in the available area on the circuit board or in the device.

Can I Use Polymer Capacitors in Place of All Electrolytic Capacitors in a Circuit?

While polymer capacitors can frequently take the place of electrolytic capacitors, it’s crucial to consider the particular needs of the circuit. Electrolytic capacitors’ self-healing abilities or special qualities in some circuits may make them more appropriate for a given application.

Conclusion

It is crucial to thoroughly consider the aspects outlined in the article when thinking about switching from electrolytic to polymer capacitors. A successful capacitor substitution depends on consulting datasheets, getting expert advice, and making sure the replacement is compatible with the requirements of the circuit.

![[Answered] What Is The Shelf Life Of Capacitors?](https://www.electronicstalk.org/wp-content/uploads/2023/12/What-Is-The-Shelf-Life-Of-Capacitors-768x431.webp)

![[Explained 4 Facts] Do Capacitors Expire?](https://www.electronicstalk.org/wp-content/uploads/2023/09/do-capacitors-expire-768x431.webp)