Solder Sponge vs Brass | A Comparative Analysis

When it comes to soldering, having the right tools can make all the difference in the quality of your work. Two common options for cleaning your soldering iron tip are the solder sponge and brass wire. In this article, we’ll compare these two options to help you make an informed choice for your soldering needs.

Choosing Between Brass and Solder Sponge | Important Considerations

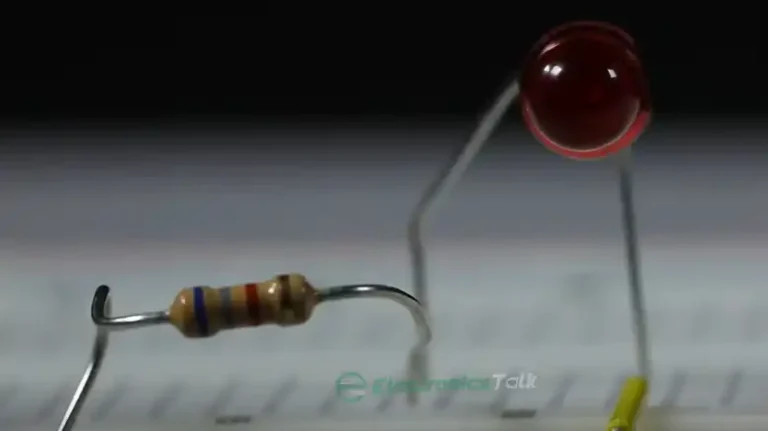

Figure: Solder Sponge and Brass

To determine the feasibility of the tools, several factors must be considered, including effectiveness, maintenance, convenience, and others.

Cleaning Effectiveness

Cleaning Effectiveness is a critical factor that directly impacts your soldering quality.

Solder Sponge

The solder sponge, typically made of a wet cellulose material, excels at removing excess solder. Pressing the hot iron onto the wet sponge instantly cools and cleans the tip, effectively removing solder residues.

Brass Wire

Brass wire is excellent at scraping away stubborn residues from the tip. The abrasive nature of brass allows it to remove old and stubborn solder, ensuring a clean and polished soldering tip.

The solder sponge is ideal for regular cleaning, while the brass wire is great for heavy-duty tip maintenance.

Maintenance and Lifespan

Maintenance and Lifespan considerations are essential for budget-conscious and practical soldering enthusiasts.

Solder Sponge

Solder sponges need to be moistened regularly. They can wear out over time and might need replacement, adding to maintenance costs.

Brass Wire

Brass wire lasts longer and doesn’t require replacement as frequently. It is a more cost-effective option in the long run.

Brass wire is the winner when it comes to longevity and cost-effectiveness.

Heat Retention

Heat Retention plays a pivotal role in the efficiency of your soldering work.

Solder Sponge

The wet nature of the solder sponge can cause a slight drop in tip temperature when cleaning. This can be inconvenient for some soldering applications.

Brass Wire

Brass wire maintains the tip’s temperature as there’s no moisture involved, making it more suitable for continuous soldering.

Brass wire takes the lead in maintaining consistent heat.

Environmental Impact

Considering the environmental impact of your soldering choices is becoming increasingly important.

Solder Sponge

Solder sponges need water for moistening, which might not be ideal for those concerned about water conservation.

Brass Wire

Brass wire is a more environmentally friendly option, as it doesn’t require water usage.

Brass wire triumphs due to its environmental friendliness.

Portability and Convenience

Portability and Convenience can significantly influence your choice, particularly if you’re frequently on the move with your soldering equipment.

Solder Sponge

Solder sponges are compact and easy to carry, making them a good choice for on-the-go soldering.

Brass Wire

Brass wire can be less convenient to carry and use in mobile soldering situations.

Solder sponge is the better choice for portability.

Frequently Asked Questions

Can I use a regular household sponge as a solder sponge?

It’s not recommended. Solder sponges are specially designed to withstand high temperatures and are made from non-flammable materials.

How do I moisten a solder sponge?

Simply use distilled water to moisten the solder sponge. Do not use tap water, as it may contain impurities that can affect the soldering iron tip.

Can brass wire damage my soldering iron tip?

Brass wire is abrasive but generally safe for soldering iron tips. However, excessive or rough use can wear down the tip over time. It’s important to use brass wire gently.

Is there a specific type of brass wire I should use for soldering?

You can use any soft brass wire for soldering, typically labeled as “soldering iron tip cleaner” or “brass soldering tip cleaner.” These are designed for this purpose.

Are there any alternatives to brass wire and solder sponges for cleaning soldering iron tips?

Yes, there are other options like tip tinner or tip cleaner compounds. These are often in paste or gel form and are used to rejuvenate and maintain soldering iron tips.

Can I use a solder sponge with a battery-operated soldering iron?

Battery-operated soldering irons don’t typically work well with solder sponges, as they lack the high heat necessary to maintain the sponge’s moist environment.

Conclusion

In conclusion, choosing between a solder sponge and brass wire depends on your specific soldering needs. If you require a quick and easy cleaning solution, the solder sponge is your best bet. However, if longevity, cost-effectiveness, and heat retention are your priorities, brass wire is the superior choice.

![[Easy Explanation] Do Resistors Have a Max Voltage?](https://www.electronicstalk.org/wp-content/uploads/2023/09/Do-Resistors-Have-a-Max-Voltage-768x431.webp)