Do Capacitors Fail With Age? | Answered

Capacitors, integral to electronic systems, are renowned for their role in storing and releasing electrical energy. Yet, as time passes, questions surface regarding their longevity.

Yes, capacitors can fail with age due to internal degradation, but the rate and severity depend on the type and usage.This article highlights why these essential components may falter with age.

Reasons for Capacitor Failure With Age

Capacitors are crucial components in electronics, storing and releasing electrical energy as needed. While they’re designed to last for a long time, they can fail over extended periods due to various reasons associated with aging and environmental factors. Here are some common reasons why capacitors might fail with age:

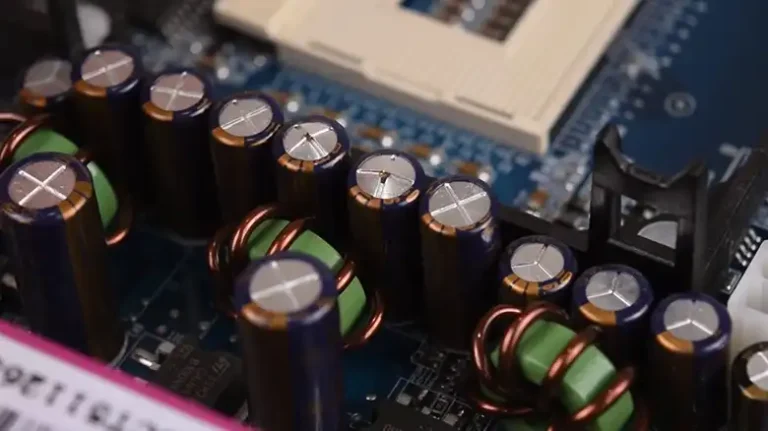

Electrolyte Drying Out

Electrolytic capacitors, particularly aluminum electrolytic ones, contain a liquid electrolyte that can dry out over time. This electrolyte maintains the capacitor’s functionality and capacitance. As it evaporates or degrades, the capacitor’s performance diminishes, leading to failure.

Temperature Stress

Capacitors are sensitive to temperature fluctuations. Prolonged exposure to high temperatures, thermal cycling (repeated heating and cooling), or operating at temperatures beyond their specified range can degrade the capacitor’s internal components, reducing its lifespan.

Humidity and Moisture

Moisture can penetrate capacitors, especially those with inadequate sealing or improper storage. Over time, moisture can corrode internal components or cause shorts, resulting in the capacitor’s failure.

Overvoltage or Voltage Spikes

Exceeding the rated voltage of a capacitor, whether through overvoltage events or voltage spikes in the circuit, can stress the dielectric material, causing it to break down. This breakdown compromises the capacitor’s ability to store charge properly, leading to failure.

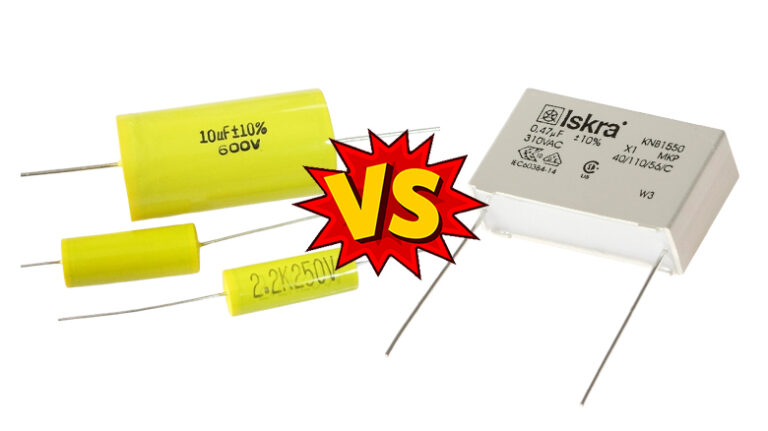

Aging of Dielectric Material

All capacitors have a dielectric material that separates the electrodes. Over time, this material can degrade due to electrical stress, temperature, and environmental factors. As the dielectric weakens, the capacitor’s capacitance decreases, impacting its performance and eventually leading to failure.

Manufacturing Defects or Quality Issues

Sometimes, capacitors might fail prematurely due to manufacturing defects or poor quality control. This could include issues with the dielectric material, electrode connection, or overall construction, leading to early failure even before the expected lifespan.

Mechanical Stress or Physical Damage

External factors such as mechanical stress, vibration, or physical damage can compromise the integrity of capacitors. Cracks or damage to the casing can expose internal components to environmental elements, accelerating failure.

End of Life (EOL) Characteristics

Capacitors, like many components, have a defined lifespan. As they approach their end of life, their parameters start drifting away from their specified values, leading to reduced efficiency and eventual failure.

Rate of Capacitor Failure With Age

The rate of capacitor failure with age varies significantly depending on multiple factors that impact their lifespan. Capacitors, while designed for longevity, are subject to aging mechanisms that can lead to eventual failure. Several key factors influence the rate at which capacitors deteriorate over time:

Type of Capacitor

Capacitor lifespans and aging vary by type. Electrolytic capacitors last 10-20 years but are prone to drying and increased leakage. Ceramic and film capacitors endure for decades with less aging. Tantalum capacitors fall in between.

Each type’s aging characteristics impact their suitability for different applications, with electrolytic capacitors favored in cost-sensitive scenarios, and ceramic/film capacitors preferred for long-term reliability.

Operating Conditions

Environmental factors such as temperature, humidity, and voltage stress greatly affect capacitor aging. Excessive heat, high humidity, or operating at voltage extremes can accelerate aging, leading to a higher failure rate.

Quality of Materials

Capacitors made with high-quality materials tend to have longer lifespans and a lower failure rate compared to those made with lower-grade components. Superior materials offer better resilience against aging factors.

Frequency of Use

Capacitors that remain idle for extended periods can experience deterioration due to reasons like electrolyte drying in electrolytic capacitors or dielectric breakdown in other types.

Manufacturing Defects

Inherent defects introduced during manufacturing can lead to premature aging and increase the failure rate. These defects might not be immediately apparent but can contribute to earlier failures.

Frequently Asked Questions

Are there ways to extend the lifespan of capacitors?

Yes, by operating within specified temperature and voltage limits, regular maintenance, proper storage, and avoiding excessive stress on the capacitors.

Are there warning signs to anticipate capacitor failure in advance?

Yes, warning signs such as increased temperature, abnormal noise, or erratic device behavior can signal impending capacitor failure.

Can capacitor failure lead to damage to other components in electronic systems?

Yes, capacitor failure, especially in the case of electrolytic capacitors, can cause damage to nearby components due to leakage or short circuits.

Conclusion

Capacitors do age, influenced by factors like temperature, stress, and material changes. Recognizing these influences is key to preserving electronic system reliability. Managing these factors ensures prolonged capacitor life, emphasizing the significance of maintenance and environmental care for sustained electronic performance.

![[Explained 4 Facts] Do Capacitors Expire?](https://www.electronicstalk.org/wp-content/uploads/2023/09/do-capacitors-expire-768x431.webp)