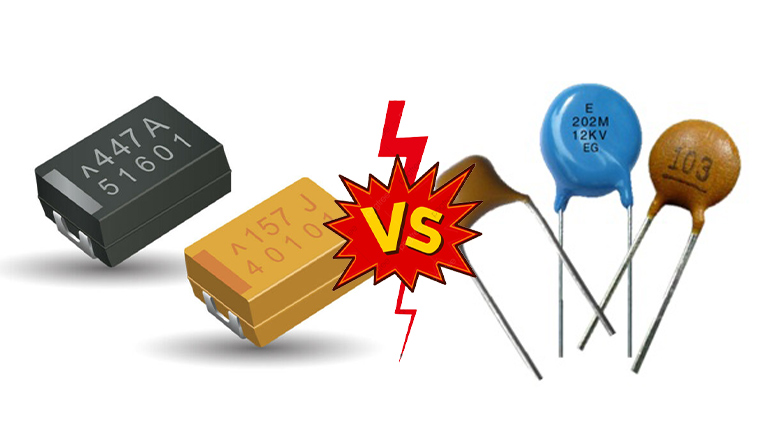

Tantalum vs Ceramic Capacitor | Multi-faced Analysis

Tantalum and ceramic capacitors are similar in their function but different in construction, performance, and materials. They usually differ in aging, polarization, temperature response, voltage response, etc.

Tantalum vs Ceramic Capacitor – Which One?

Tantalum capacitors are a type of electrolytic capacitor in which the anode is tantalum metal. Tantalum capacitors offer better frequency characteristics and are more stable in the long run.

Ceramic capacitors are one of the most common types of capacitors with a ceramic dielectric. These capacitors are compact, with a lower maximum rated voltage and lower capacitance values. Here are the factors that make tantalum and ceramic capacitors distinct from each other.

Aging

When it comes to capacitors, aging refers to a logarithmic decline in capacitance over time. Tantalum capacitors do not age, whereas ceramic capacitors do. There is no known wear mechanism for tantalum capacitors.

Polarization

Tantalum capacitors are usually polarized. This implies they can only be connected to a DC power source while maintaining proper terminal polarity. Non-polarized ceramic capacitors, on the other hand, can be safely linked to an AC source. Ceramic capacitors have a superior frequency response since they are not polarized.

Temperature Response

Tantalum capacitors have a linear capacitance change when exposed to temperature fluctuations, but ceramic capacitors have a non-linear response. Ceramic capacitors, on the other hand, can be made to trend linearly by reducing the operating temperature ranges and taking temperature response into account during the design phase.

Voltage Response

Tantalum capacitors offer constant stability when looking at capacitance changes with applied voltage, whereas ceramic capacitors do not. The permeability of the dielectric shrinks within the ceramic capacitor in response to increasing applied voltages, causing capacitance variations.

Though most ceramic capacitor capacitance changes are linear and easily accounted for, some higher transmittance dielectrics can lose up to 70% of their initial capacitance when run at rated voltage.

Are Tantalum Capacitors Better Than Ceramic?

Better can’t be used as an exact word for these two capacitors. Ceramic capacitors have outdone tantalum capacitors in some segments. However, tantalum capacitors have some significant specifications that make them better in numerous cases. As mentioned before, tantalums are polar, which means they can only be utilized with a specific polarity of DC bias.

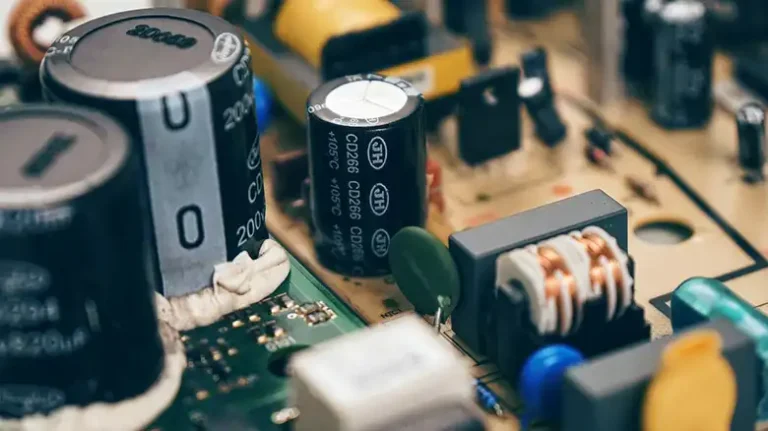

Tantalum electrolytics, like aluminum electrolytics, give a high capacitance in a compact space. Tantalum electrolytics have a lower equivalent series resistance (ESR) than aluminum electrolytics, as well as lower leakage current, better tolerance, and smaller physical packaging. They are, however, more expensive, owing to tantalum’s status as a “conflict” mineral.

Ceramics are commonly employed as general-purpose bypass caps and in a variety of other applications. They can be utilized in a wide range of applications, from audio frequency circuits to RF/microwave, however, they don’t have the capacitance per unit volume to be employed in power supply filtering.

Can I Replace a Tantalum Capacitor With a Ceramic?

Some system engineers prefer ceramic capacitors over tantalum capacitors in their applications for a variety of reasons, including reduced cost, smaller size, and dependability.

Ceramic capacitors have a broad tolerance and their capacitance fluctuates depending on the voltage. These capacitors are often larger than tantalum capacitors of equal value but have a lower ESR.

In most instances where a tantalum capacitor is used for decoupling, a ceramic capacitor should be able to replace it if it fits in the space. However, replacing a tantalum capacitor with a ceramic capacitor would not be a smart idea if the tantalum capacitor is used for audio coupling or timing.

What Is the Advantage of Tantalum Capacitors?

Tantalum capacitors have several advantages over other capacitor types. As a result, their use has increased significantly over time, and they are now widely utilized in all types of electronic equipment. The benefits of tantalum capacitors can be summarized as follows below.

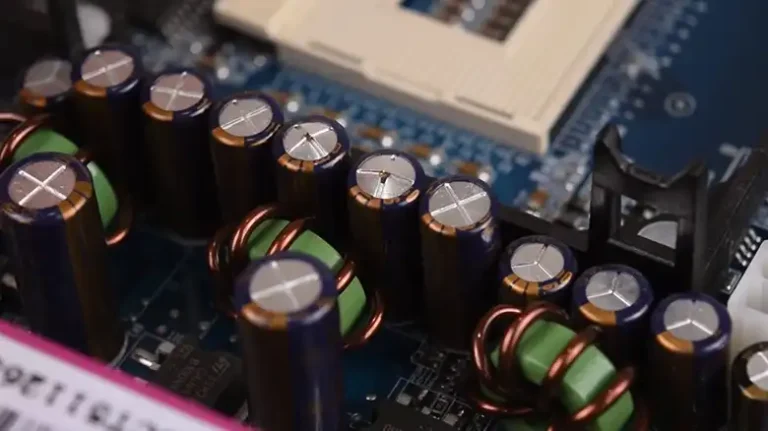

Volumetric Efficiency

Tantalum capacitors have a substantially higher volumetric efficiency than many other capacitor types. They are superior to electrolytic capacitors, which are their major competitors.

Good Frequency Characteristics

Tantalum capacitors have a better frequency response than electrolytic capacitors. This implies they’re better suited to a variety of applications where electrolytics aren’t an option.

High Reliability

Tantalum capacitors have higher dependability than many other types of capacitors. They can provide an almost limitless life provided they are operated within their ratings. Unlike electrolytic capacitors, their use is not restricted in time.

Wide Operating Temperature Range

Tantalum capacitors have a wide operating temperature range and can be used in a variety of applications. They are frequently indicated for temperatures ranging from -55 to +125 degrees Celsius. This makes them an excellent choice for equipment that will be used in harsh environments.

Compatibility With Modern Production Methods

Since the entire assembly is heated by infrared heat, modern manufacturing procedures frequently expose components to high temperatures during soldering. Only the board surface was heated when using typical leaded components.

The quantity of heat transferred via the leads was usually inadequate to damage the components. Tantalum capacitors can resist the high temperatures of SMT manufacturing, making them excellent for usage in a variety of modern electronic designs.

What Is Wrong With Tantalum Capacitors?

There are some considerations in terms of tantalum capacitors while using them in new designs. They are listed below.

Low Ripple Current Ratings

Given their size, it’s not unexpected that tantalum capacitors have a low ripple current rating. They shouldn’t be used in locations where any amount of current needs to be passed.

Not Tolerant to Reverse or Excess Voltage

Tantalum capacitors are sensitive to reverse and excessive voltage. They’re vulnerable to even surges. They can explode if they are exposed to excessive or reverse voltages.

More Expensive

Tantalum capacitors are costlier than many other types of capacitors. As a result, their cost should be taken into account throughout the design phase, as the other advantages may surpass any additional expenditures.

Also, the disadvantage of employing tantalum capacitors is that they have an unfavorable failure mode, which can result in thermal runaway, fires, and tiny explosions. However, this can be avoided by utilizing external failsafe devices such as current limiters or thermal fuses.

Final Words

Tantalum and ceramic capacitors both provide numerous advantages and benefits. However, because the composition, materials, and performance of both capacitors differ greatly, the decision to choose one over the other is based on specific application considerations and requirements.

![Can I Replace a 16V Capacitor With an 25V Capacitor? [7 Comparison Aspects Explained]](https://www.electronicstalk.org/wp-content/uploads/2023/07/Can-I-Replace-a-16V-Capacitor-With-a-25V-Capacitor-768x431.webp)

![Can I Use 25V Capacitor Instead of 35V? [Technically Explained]](https://www.electronicstalk.org/wp-content/uploads/2023/07/Can-I-Use-a-25V-Capacitor-Instead-of-35V-768x431.webp)

![Can I Use a 63V Capacitor Instead of 25V? [Technically Explained]](https://www.electronicstalk.org/wp-content/uploads/2023/07/Can-I-Use-a-63V-Capacitor-Instead-of-25V-768x431.webp)