Do Capacitors Degrade if Not Used | Factors and Solution

The current shelf life of aluminum electrolytic capacitors is about 2 years. When these capacitors are stored at high temperatures, the sealing material can fail. So, they degrade if not used. When the material deteriorates, the electrolyte dissipates, changing the properties of the capacitor values.

Regular maintenance, repair, or swapping of electrolytic capacitors should be scheduled to prevent electrolytic capacitor degeneration in essential circuits. The fundamental mechanism that causes electrolytic capacitor degeneration and failure is the steady evaporation of the electrolyte over time.

This is exacerbated at higher temperatures. As a result, capacitance is reduced and effective series resistance (ESR) is increased.

What Reduces the Lifespan of a Capacitor

Mainly environmental factors play a significant role in the degradation of an unused capacitor. The factors are illustrated below with their respective solution that can mitigate the degradation.

1. Service Life

You must take a capacitor’s service life into account. As the temperature rises, so does the service life.

Figure 1: Datasheet of lifespan for a B41888 capacitor.

Solution

If you want to store a capacitor, ensure that its service life is more than the time that you want it to store.

2. Capacitance

Depending on the dielectric, the capacitance will fluctuate with temperature. This is induced by a change in the dielectric constant as well as the dielectric material/electrodes themselves expanding or contracting. Excessive clamping pressures on non-rigid enclosures might cause capacitance changes.

Solution

Ensure that the capacitance stays constant for the capacitor that you’re storing. As a result, the materials of the capacitor won’t expand or contract. So, it won’t degrade fast.

3. Insulation Resistance

The insulating resistance of a capacitor reduces as its temperature rises. This is because electron activity has increased. Moisture trapped in the windings, extended exposure to extreme humidity, or moisture trapped during the manufacturing process can all cause low insulation resistance.

Solution

Ensure that the surrounding of the capacitors stays cool and dry. If the insulation resistance doesn’t change, your capacitor won’t degrade that fast.

4. Dissipation Factor

The dissipation factor is a complicated function that is connected to the “inefficiency” of the capacitor. Depending on the dielectric substance, the “D.F.” may grow or decrease with increasing temperature.

Solution

Ensure that the D.F. doesn’t change over time. Keep calculating the D.F. of the unused capacitor within short periods.

5. Dielectric Strength

As the temperature rises, the dielectric strength (dielectric withstanding voltage or “stress” voltage) drops. This is related to the dielectric material’s chemical activity, which produces a change in the physical or electrical properties of the capacitor.

Solution

Ensure that the surrounding temperature of the unused capacitor stays exactly the way that is necessary to preserve its dielectric strength.

6. Shock, Vibration, and Acceleration

If a capacitor is not designed, manufactured, or installed to meet the vibration, shock, or acceleration requirements of a certain application, it might be mechanically destroyed or malfunction.

Low I.R., shorts, and openings might result from the movement of the capacitor within the casing. Fatigue in the leads or the mounting brackets can also result in catastrophic failure.

Solution

Ensure that the capacitor is stored in a place that doesn’t face too much movement.

7. Pressure in the Barometric System

The voltage rating of hermetically sealed capacitors is determined by the altitude at which they are to be used. The terminal “arc-over” susceptibility increases as barometric pressure lowers. Internal pressure variations can cause internal strains in non-hermetic capacitors.

Solution

Store the capacitor in a place that has an ideal barometric pressure that is necessary to keep the capacitor okay for a longer period.

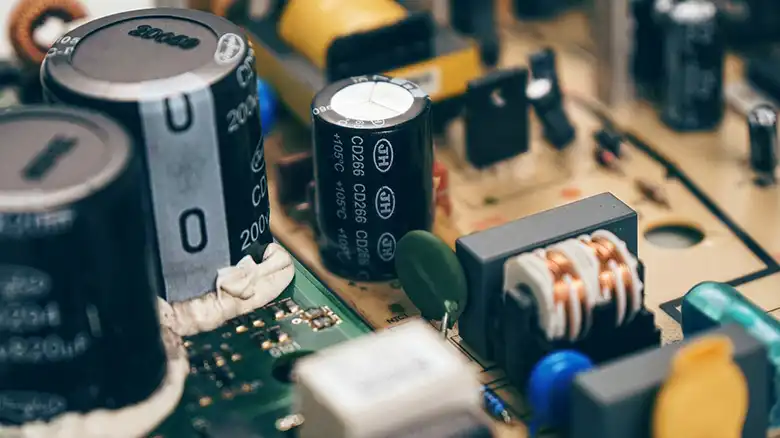

How Can You Increase the Life of a Capacitor?

When the working voltage is lower than the maximum rated voltage, you can get a reasonable increase in longevity. The most conservative estimate is that when the component is run at 50% of its rated voltage, its lifespan doubles.

Conclusion

The advantage of capacitors is that they often have a longer lifespan than batteries, making them a more ecologically friendly solution. They can also release energy much faster than a battery, making them ideal for applications that require a brief but powerful burst of power.

![[Answered] What Is The Shelf Life Of Capacitors?](https://www.electronicstalk.org/wp-content/uploads/2023/12/What-Is-The-Shelf-Life-Of-Capacitors-768x431.webp)

![[Answered & Explained] Does Size Matter in Capacitor?](https://www.electronicstalk.org/wp-content/uploads/2023/10/Does-Size-Matter-in-Capacitor-768x431.webp)